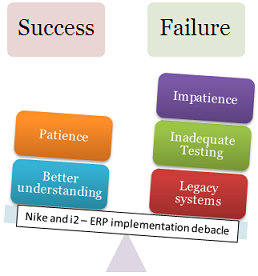

In June 2000, Nike’s new supply-and-demand software planning system implementation from i2 Technologies had hiccups and led to losses of $400 million. This case study highlights the failure and subsequent success of ERP implementation in Nike’s supply chain project.

Case Study – Table of Contents

- Introduction – Supply chain management problems at Nike

- Nike Background

- Nike’s Futures – An advance-order purchase system

- Nike’s supply chain project – from make-to-sell to make-to-order

- An ERP solution gone bad

- Playing the blame game. What went wrong?

- Nike’s business model and Inadequate Data problems

- The Turnaround

- Questions for discussion

- Bibliography

- Exhibit 1 – Nike Quick facts

- Exhibit 2 – Various ERP providers at Nike

- Exhibit 3 – How Successful ERP Selections Are Made

- Exhibit 4 – Lessons from Nike’s i2 disaster

- Exhibit 5 – Top Supply Chain Disasters

- Exhibit 6 – Symptoms of ERP implementation failures

- Exhibit 7 – i2 TradeMatrix Plan Solution

- Chart 1 – Nike – 10 year Financial History

Sample Page

1.Introduction – Supply chain management problems at Nike

In February 2001, Nike, the athletic shoe and clothing giant had warned that its third-quarter footwear sales were not up to the mark and as a result, its year-over-year sales for the third quarter would be flat. Nike’s stock price fell almost 20% the day this announcement came while i2’s stock plunged nearly 22 per cent. (Nike’s footwear division was powered by i2 Technologies.)

The problem – Nike’s new supply-and-demand software planning systems from i2 Technologies had hiccups in June 2000. The software incorrectly output orders for thousands more Air Garnett sneakers than the market had appetite for and called for thousands fewer Air Jordan’s than were needed. As a result, there were huge inventory problems and overdue deliveries.

Download case study PDF to read more…